Ema 5646 ceramic processing zhe cheng 2015 3 powder characterization powder characteristics critical to starting material quality control microstructural control of processed ceramic body powder characterization critical to chemical composition phase composition.

Ceramic powder characterization.

This work was systematically divided into three parts.

The diffraction pattern of pure yag powder made by one co precipitation process is shown in fig.

University of florida department of materials science and engineering 100 rhines hall p o.

N2 the generation of a pressure density curve by automatic means is demonstrated to be a reliable method for characterizing the compaction response of a granulated ceramic powder.

Characterisation methods for ceramic powders and green bodies.

Au mccoy larry g.

Au markhoff carole j.

However there is an extended number of examples showing that the properties of the starting powder have a strong impact on the final products 9 properties.

Box 116400 gainesville fl 32611 6400 usa.

Characterization of ceramic powders 41 involving the co precipitation of y 3 a1 5 0 1 2 yag from aqueous solution.

These characteristics include particle shape surface area pore size distribution powder density and size distribution.

T1 characterization of ceramic powder compaction.

The first part deals with the characterization of two phase barium titanate cyanoethyl ester of polyvinyl alcohol polymer ceramic composite in.

This chapter discusses the various techniques of ceramic powder characterization.

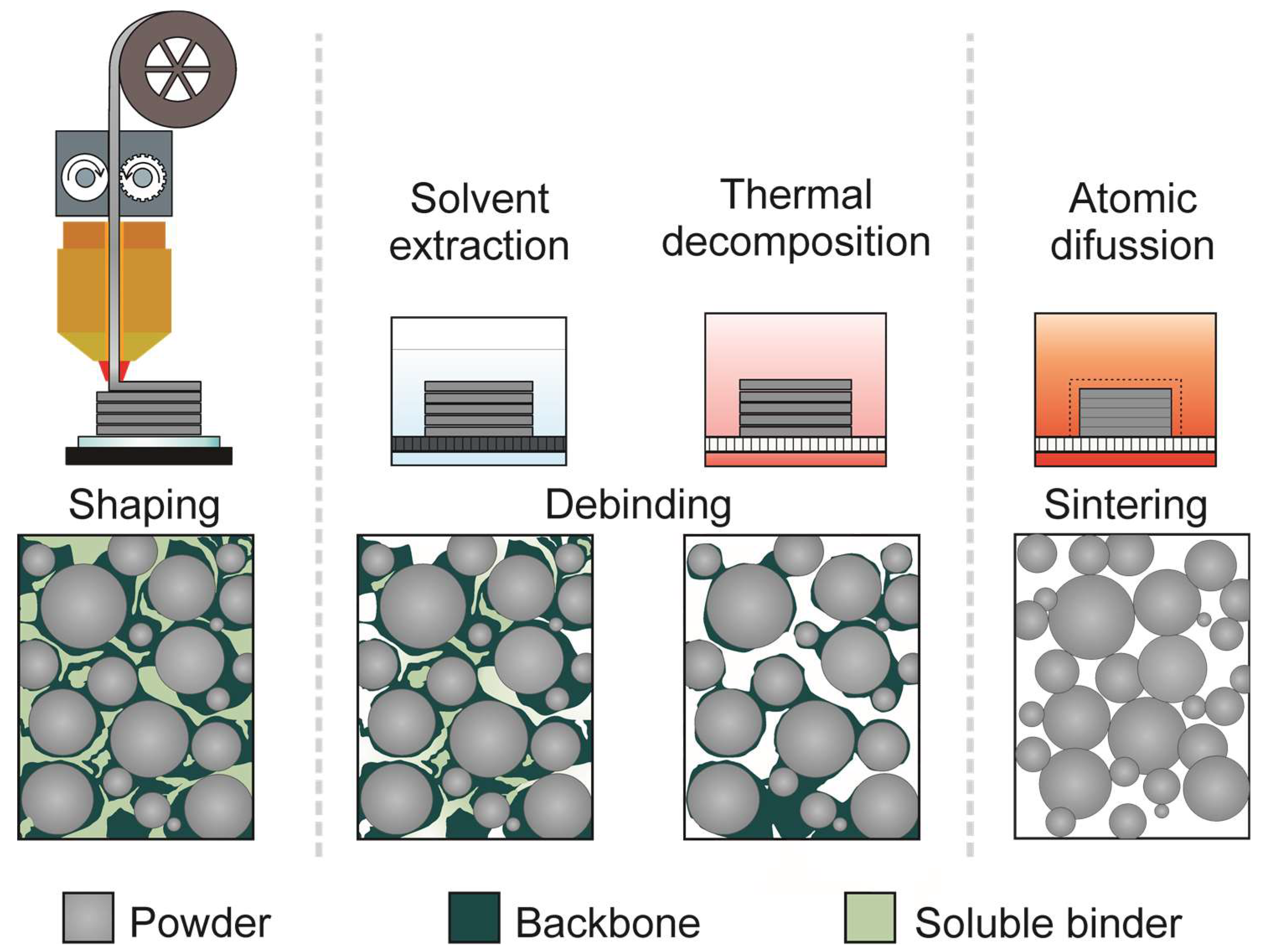

Ceramic manufacturing based on powders shape compaction and subsequent densification is a process combining a number of different independent steps.

In particular the packing of the ceramic particles and the viscosity of the dispersion are strongly impacted by the physical properties of the ceramic powder used in preparation of the slurry.

Au messing gary l.

The objective of this twa was the development and standardization of test methods for the characterization of ceramic powders and green bodies as they are related to the different stages of the ceramic manufacturing process.

Powder characterization for ceramic processing using astm test methods.

The performance and rheology of ceramic slurries are dependent upon many factors.

Figure lb resulted from a different co precipi tation technique in addition to yag ya10 3 h and y 4 a1 2 0 9 2 1 were.

The objectives of the iea subtask 10 were to evaluate test methods for the characterization of selected properties of ceramic powders through an international round robin study and to determine the repeatability and reproducibility of the test methods.

The activities were conducted under the auspices of the international energy agency iea.

E g al 2 o 3 vs.