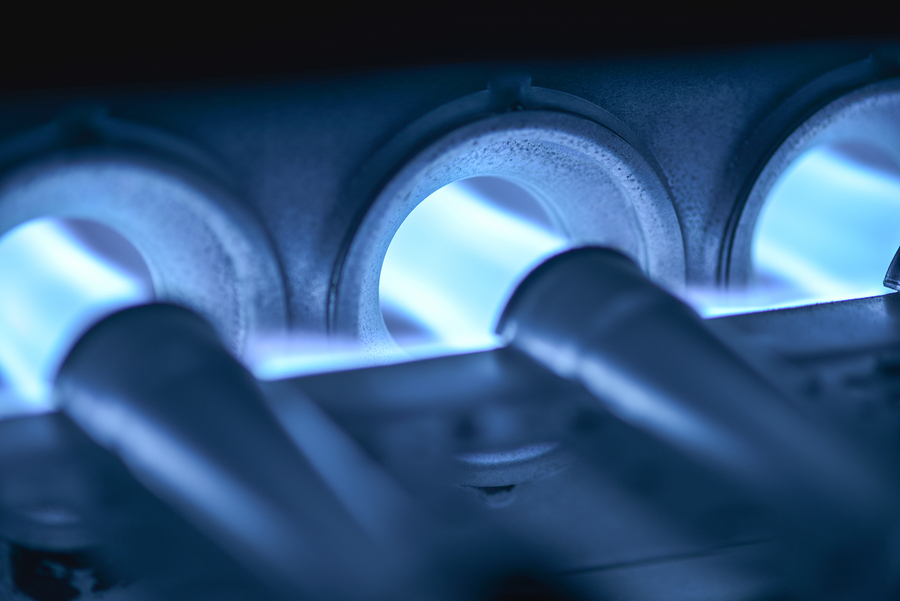

Burner and tube designs that get more of the heat out of the tube and into the furnace process have become more common as energy prices increased.

Ceramic furnace burner tube inserts.

Production capabilities include isostatic and dry pressing low pressure injection molding extrusion slip casting and cnc machining.

36 kw with ceramic burled tube recuperator made of sisic recuperator length.

545 mm with staged combustion for natural gas for direct heating with eductor burner head identifier 31 constru.

Alumina furnace tube coe.

Furnace tubes machinable and fully dense ceramic materials for applications in which high temperature insulation thermal shock resistance and high dielectric strength are required.

A wood burning stove or wood burner or log burner in the uk is a heating appliance capable of burning wood fuel and wood derived biomass fuel such as sawdust bricks.

Their advantages in comparison to conventional tubes made of heat resistant high quality steel or monolithic ceramics include durability and reliability at temperatures up to 2450.

For heating of furnace systems burner size 1 rated capacity.

This page will contain information about technologies developed to increase burner tube efficiency.

Generally the appliance consists of a solid metal usually cast iron or steel closed firebox often lined by fire brick and one or more air controls which can be manually or automatically operated depending upon the stove.