Use vent system at the source.

Ceramic dust exposure.

Crystalline silica is a basic component of soil sand granite and many other minerals.

Lead compounds are highly toxic by inhalation or ingestion.

Ceramic arts crafts production and lab testing can generate a lot of dust if it is not managed properly.

Time exposure is what matters.

Ceramic educational programs are coming under increased scrutiny because of dust concerns.

Dust masks must fit well and they must be specifically designed for very fine dust.

Dust masks should be used if and when dust cannot be avoided.

Use only a niosh national institute for occupational safety and health approved masks rated for fine toxic dust.

For example the injury caused by exposure to silica is marked by islands of scar tissue surrounded by normal lung tissue.

Sweep or making clay just before you leave at night allows dust to settle.

Cristobalite and tridymite are two other forms of crystalline silica.

This simply means dusty lung.

Glaze components are weighed sorted and mixed with water.

Or in another room.

Ventilation is the key.

Many masks are sold in drug stores that do not qualify.

The changes which occur in the lungs vary with the different types of dust.

Most of the following suggestions will greatly reduce your exposure to dust taken together they should make your workplace safe.

Glazes can be dipped brushed poured or sprayed on the ceramic piece.

Some types of lung diseases caused by the inhalation of dust are called by the general term pneumoconiosis.

All three forms may become respirable size particles when workers chip cut drill or.

Kilns should be vented properly.

When someone inhales silica dust the particles can attach to the lining of the lungs causing scar tissue and fluid buildup.

Pick up the dust before it gets into the studio.

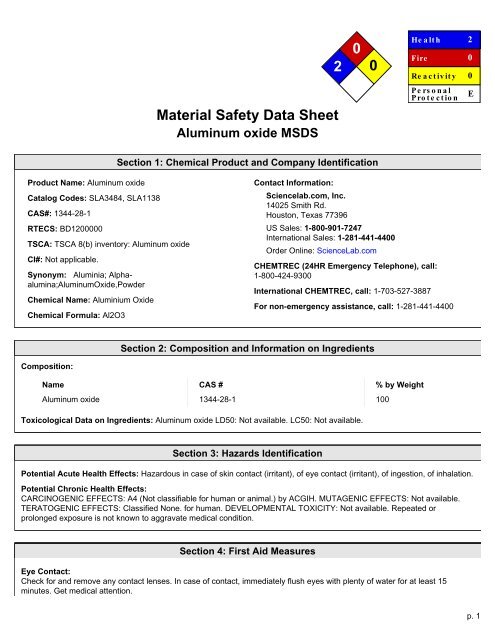

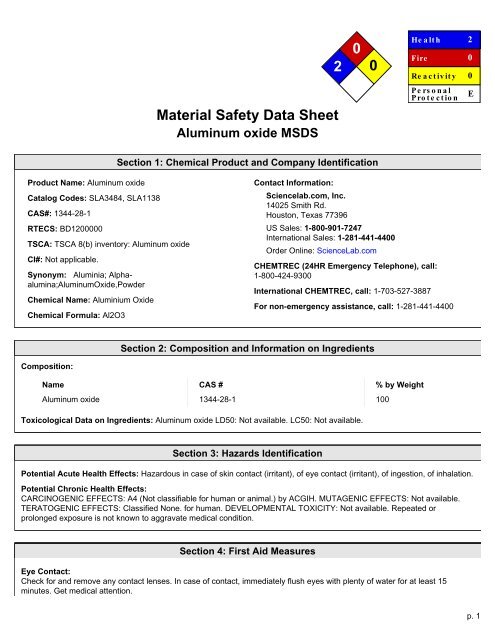

Workers who use porcelain ceramic and clay products are at risk for exposure to toxic minerals and substances.

Quartz is the most common form of crystalline silica.